Clearance and fixing requirements for high voltage harness layout

High voltage harness is one of the core components of new energy vehicles. Compared with low-voltage harness, the layout of high-voltage harness is slightly different. This paper mainly introduces the layout clearance requirements and fixing requirements of high-voltage harness.

1、 Clearance requirements

The layout clearance shall be appropriate, and the operability of assembly and repair shall be fully considered.

Generally, no less than 200mm space shall be reserved at all joint positions for connection and disconnection operation. The connection between the connector and the element shall be properly relieved of mechanical stress.

In view of different current sizes, the distance between high and low voltage parallel lines of commercial vehicles shall be greater than 400mm, and the distance between high and low voltage parallel lines of passenger vehicles shall be greater than 200mm; If the actual situation does not meet this distance, we can consider routing perpendicular to each other.

2、 Fixing requirements

For high voltage harness layout, the harness shall be protected as much as possible to minimize the relative movement between the harness and the vehicle body.

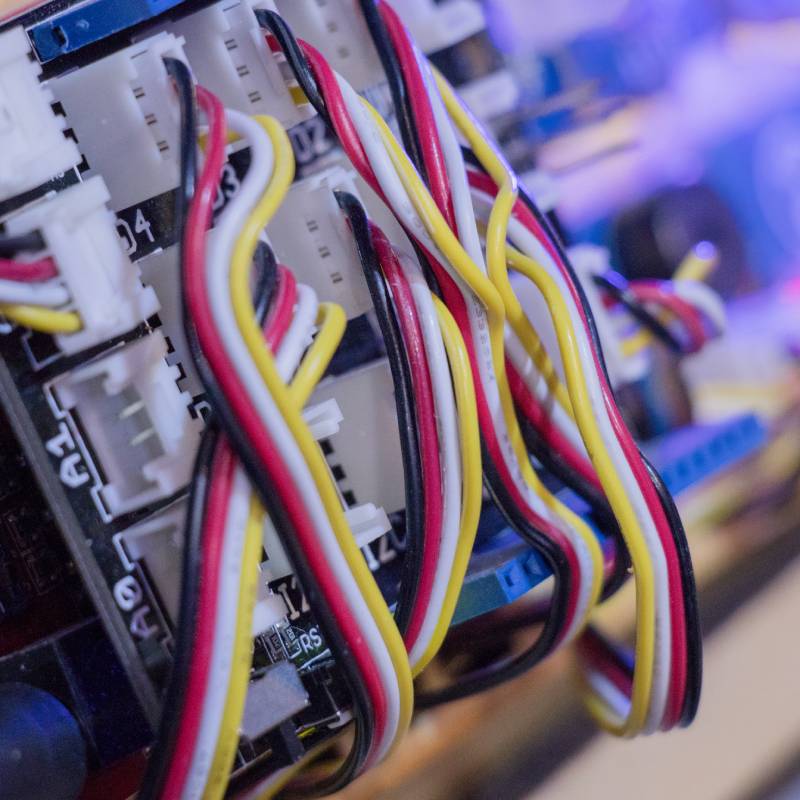

Due to the high strength of the high-voltage harness, it needs to be treated according to the length of the harness. Generally, smooth and burr free supports, trunking, clamps and ties can be used for fixation; When fixing the tie, the fixing method shall be fully considered in order to select the appropriate tie to avoid failure.

The distance between harness and protective parts shall not exceed 400mm. Moreover, the high-voltage harness shall not interfere with the moving parts, and the distance between them shall not be less than 50mm.

The power battery of the pure electric vehicle is placed in the lower floor behind the vehicle, led from the front end of the battery to the high-voltage harness, which passes under the vehicle bottom and is close to the ground. It needs to be protected by corrugated pipe outside the cable to prevent stone hammer caused by road splash during driving.

In some places, due to space requirements, the harness cannot be protected by bellows. The scheme of adding plastic trunking outside the high-voltage harness can be considered to protect the harness.