FPC soft board process and overall performance

The process of FPC soft board includes exposure, PI etching, opening, electrical test, stamping, appearance test, performance test, etc. The manufacturing process of FPC soft board is related to the performance of FPC. After manufacturing, unqualified FPC soft boards need to be screened through testing to ensure that FPC maintains good performance and plays the best role in application. In FPC soft board testing, high current shrapnel microneedle module with conduction and connection functions can be used to ensure the stability and efficiency of FPC soft board testing.

The FPC soft board process of electronic Valley uses exposure to transfer circuit patterns to the board through dry film, usually using photosensitive method. After exposure, the circuit of FPC soft board is basically formed, and the dry film can transfer the image to protect the circuit during etching. PI etching means that under certain temperature conditions, the etching solution is evenly sprayed on the surface of copper foil through the nozzle, redox reaction occurs with copper, and then the film is removed to form a circuit. The purpose of the opening is to form the original conductor line and form the interlayer interconnection line. The opening process is usually used for the conduction connection of the upper and lower layers of double-layer FPC.

In addition to service life, reliability and environmental performance, the performance indexes of FPC soft board also include bending resistance, bending resistance, heat resistance, solvent resistance, weldability, peeling, etc.

The bending resistance and bending resistance of FPC flexible board are related to the material and thickness of copper foil, the model and thickness of rubber used for base material, and the material and thickness of insulating base material. In the assembly technology of FPC flexible board, double-layer and multi-layer FPC copper foil has good symmetry, bending resistance and bending resistance.

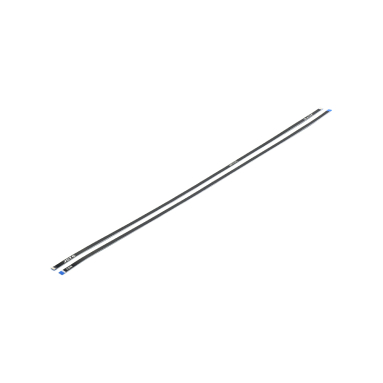

FPC soft board testing requires professional equipment, in which the high current shrapnel micro needle module has stable guiding function, and the integrated shrapnel design has the characteristics of high overall accuracy and good conductivity. In large current transmission, it can carry current in the range of 1-50a and has reliable overcurrent capacity. The current flows in the same material, the voltage is constant, the current does not decay, and the performance is stable and reliable.

In a small pitch, the high current shrapnel microneedle module can cope with the pitch value between 0.15mm and 0.4mm and maintain a stable connection. It does not jam pin pins, and has excellent expressiveness and service life. After gold plating and hardening, the average service life of shrapnel can reach more than 20W, which can greatly improve the test efficiency of FPC soft board without frequent replacement, and avoid material waste and unnecessary loss.

In terms of performance and cost performance, the high current shrapnel microneedle module is a very reliable choice and has irreplaceable advantages. It can not only ensure the stability of the test, but also improve the test efficiency of FPC soft board and ensure the quality of FPC soft board.