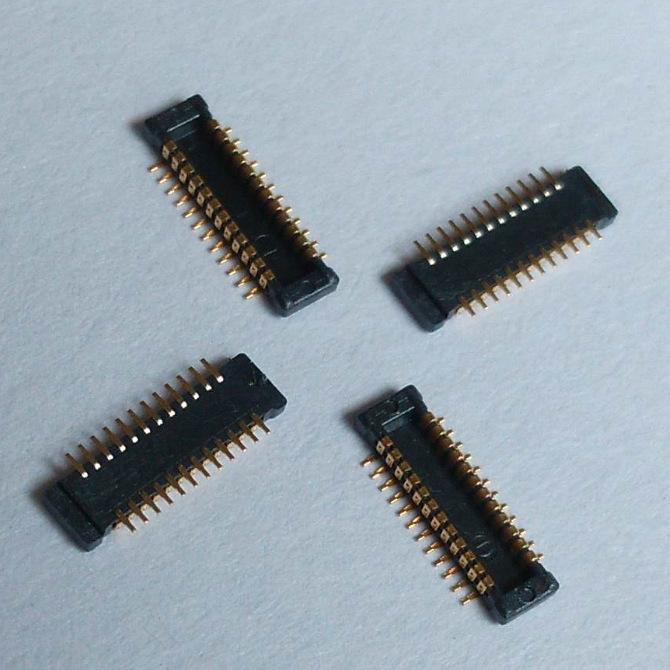

Process introduction of BTB connector

Use in electronic products BTB connector , it can play the role of high-speed transmission, and the micro BTB connector is the most beneficial. It is not only flexible, convenient and practical, but also in line with the current trend and widely used.BTB connector It can be divided into side insert type, single slot type, double slot type and other forms. According to its performance, it can be divided into mechanical performance, electrical performance, anti-corrosion performance and so on. The performance of BTB connector is closely related to manufacturing process and quality test BTB connector The production steps can analyze its quality.

I BTB connector The production steps of.

1. Stamping. Starting from the stamping plug of the stamping machine, one end of the metal belt enters the front end of the stamping machine, and the other end is wound on the winding pulley for stamping manufacturing;

2. Plating. The coating process is mainly to coat the contact surface of the connector with a layer of metal coating. In the coating process, it is easy to find whether the connector has distortion, deformation and other problems. This process can improve the performance of BTB connector;

3. Injection molding. The injection molding process is conducive to the molding of the connector, can improve the bite force, and all parts of the fixed BTB connector can not fall off. After the injection,BTB connector After the assembly is completed, the quality and performance can be tested. The test is conducive to improve the output rate of products, detect defective products and reduce the production cost.

In the BTB connector test, the shrapnel micro pin module has a good guiding function, can transmit large current, has stable performance in the range of 1-50a, has almost no attenuation of current, has strong adaptability in small pitches, does not jam pins during connection, keeps pins, and has an average life of 20W times.

2、 How to improve BTB connector Performance.

The coating process can be effectively improved BTB connector Mechanical performance, electrical performance and anti-corrosion performance.

1. Mechanical properties of BTB connector. The coating process will affect the durability, wear resistance, ductility, hardness, combining force and friction of BTB connector. High quality electroplating materials and technology will greatly improve the mechanical properties of BTB connector.

2. Electrical performance of BTB connector. The contact interface of BTB connector is plated with metal film to optimize the electrical performance of BTB connector and maintain stable impedance. Precious metals are selected for coating, which has better stability.

3. Anti corrosion performance of BTB connector. The contact coating of BTB connector has important anti-corrosion effect and can close the contact shrapnel to avoid environmental pollution. Copper alloy materials used in the past are easy to oxidize and have been out of the game. When selecting coating materials, they must have anti-oxidation and anti vulcanization functions to improve the anti-corrosion performance of BTB connectors.

Shenglan Technology Co., Ltd_ It focuses on the production of electronic connectors and research and development of precision components. Its products are widely used in consumer electronics, new energy vehicles, USB, 5g and other fields. Its industrial lines cover the Pearl River Delta, Southeast Asia and other regions. It has established long-term strategic cooperation relations with well-known enterprises such as Foxconn, Lixun precision, Huawei, Xiaomi, TCL, Hitachi Group, BYD and Great Wall Motors, with IATF 16949, ISO9001 ISO14001, QC080000 and other system certification and product safety certification, and provide professional connection and manufacturing solutions for the industry http://jctc.com.cn/