Why does the connector fail? What's the reason!

The relativity of the internal electrical conductor of the connector in terms of the external electrical conductor, the internal electrical conductor with small specification and weak compressive strength is more likely to lead to poor contact and invalid connector.

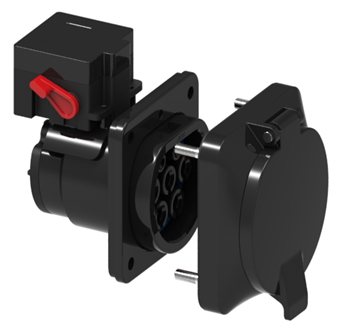

Most of the internal electrical conductors of the connector use ductile interface methods, such as elastic yellow claw ductile connection, socket slotted ductile connection, metal bellows ductile connection, etc. Among them, the socket slotted ductile buckle has the advantages of simple structure, low production cost, convenient installation and more common application.

What are the causes of connector failure?

1. The internal electric conductor is not fixed firmly

In order to better install, it is necessary that the structure of many frequency emission coaxial output connectors (such as n-type, 3.5mm) is that the internal electrical conductor is punished in two halves at the material support point, and then connected with bolts. However, because the diameter of the internal electrical conductor is small, if there is no glue dispensing at the bolted connection and it is fixed in many aspects during installation, the connection compressive strength of the internal electrical conductor is too poor, especially some small and medium-sized frequency emission coaxial output connectors. Therefore, when the connector is connected and broken several times, under the long-term effect of torque and tensile resistance, the external thread of the internal electrical conductor is likely to loosen and fall off, resulting in invalid connection.

One of the common structures of frequency emission coaxial output connector is that the internal electrical conductor, material support point and its external electrical conductor are fixed together with adhesive. If the dispensing amount of this kind of structure is insufficient or the connection compressive strength of the glue is insufficient during installation, then in the whole process of application, the dispensing place is likely to crack due to the bearing force, which will lead to the rotation or shaft diameter shaking of the internal electrical conductor. Excellent electrical contact can not be generated in the middle of the internal electrical conductor, and the connection is invalid.

Improvement method: when installing the coaxial output connector, apply appropriate conductive adhesive or external thread locking agent at the bolt connection to improve the credibility of the bolt connection. The adhesive with high compressive strength shall be used, and it must be ensured to fill all dispensing holes when dispensing; Squeeze the tap at the dispensing point of the internal electric conductor to increase the total contact area between the internal electric conductor and the adhesive to avoid the rotation of the internal electric conductor; Appropriately adjust the axial specifications and dimensional tolerances of the internal electric conductor, the external electric conductor and the material support point, so that the mutual cooperation between the internal electric conductor and the material support point, and between the material support point and the external electric conductor is a transitional cooperation, which can also make the three installed together more solid.

2. The specification of the socket or needle of the internal electric conductor is incorrect

If the diameter of the electrical conductor in the socket is lower than the required specification, when the needle of the electrical conductor in the socket is inserted into the socket, it will cause the socket to expand too much, and the shape independent variable will exceed its elastic deformation range, resulting in plastic deformation and damage to the electrical conductor in the socket; Conversely, if the diameter of the needle is too small, when the needle and the socket cooperate with each other, the gap between the needle and the socket wall is too large, the two internal electrical conductors of the connector can not be inseparably touched, the loop resistance increases, and the performance parameters of the electrical equipment of the connector will also be very poor.

Improvement method: whether the mutual cooperation between the socket and the needle is effective, we can use the insertion force and maintenance force of the standard gauge needle and the electrical conductor in the socket. For type N connectors, diameter Φ The insertion force of 1.6760 + 0.005 standard gauge needle when matched with the socket shall be ≤ 9N, and the diameter Φ 1. When 6000-0.005 standard gauge needle and electrical conductor in socket cooperate with each other, the maintenance force shall be ≥ 0.56n. Therefore, we can take the insertion force and maintenance force as a test standard, and make the insertion force and maintenance force between the needle and the socket in a suitable range according to the specification and dimensional tolerance of the adjusting socket and the needle, and the quenching and tempering treatment and processing technology of the electrical conductor in the socket.