How to choose connector - manufacturer's experience tells you!

Connector, that is, the connector commonly referred to by engineers, is used to connect two circuit boards or electronic equipment to realize power supply or signal transmission. Depending on the connector, it can also modularize the circuit, simplify the assembly process of electronic products, and facilitate the maintenance and upgrading of products. For modular circuits, the selection of connectors plays an important role.

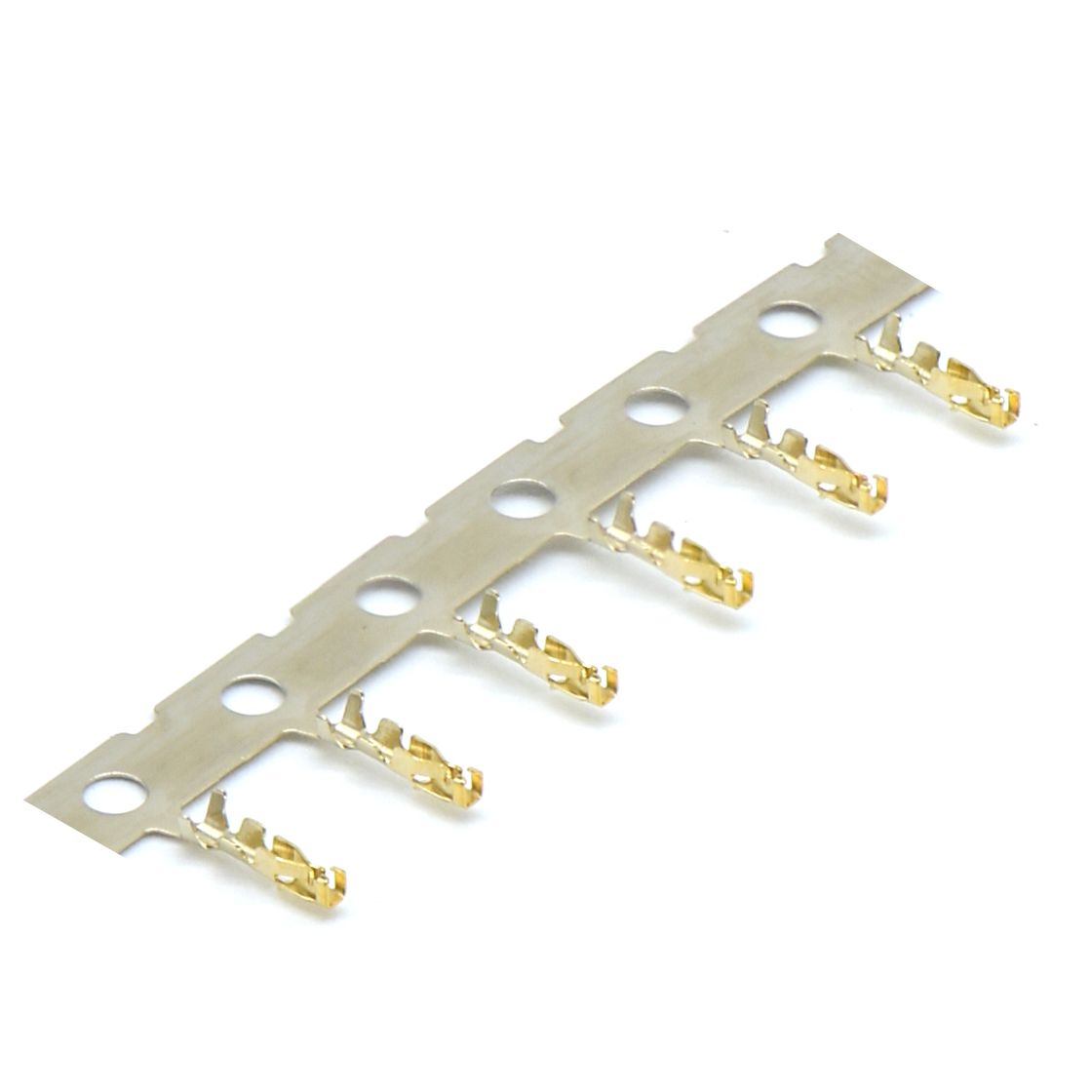

There are many kinds of connectors, including communication interface terminals, wiring terminals Wire to board connector , board to board connectors, etc. Each type can also be subdivided into several categories, such as board to board connector, including pin bar female, board to board connector, etc.Wire to board connector Including FPC connector, IDC socket, simple horn seat, etc.

Therefore, when selecting connectors, we should consider the connectors suitable for hardware from the following angles.

1. Pins, spacing.

The number and spacing of pins are the basic basis for connector selection. The number of pins selected depends on the number of signals to be connected. For patch connectors, there should not be too many patch pins. Because in the welding process of the mounter, due to high temperature, the plastic of the connector will be heated and deformed, and the middle will bulge, resulting in false soldering of the pins. If the pin is replaced by two halved pins, there will be no false soldering.

Nowadays, electronic equipment is developing towards miniaturization and precision, and the pin spacing of connectors ranges from 2.54 mm to 1.27 mm to 0.5 mm. The smaller the pin spacing, the higher the requirements for the production process. The pin spacing shall be determined according to the production process level of the company. Do not blindly pursue small spacing.

2. Electrical performance.

The electrical performance of the connector mainly includes: limit current, contact resistance, insulation resistance, resistance strength, etc. When connecting high-power power supply, pay attention to the limit current of the connector; When transmitting LVDS, PCIe and other high-frequency signals, pay attention to the contact resistance. The connector shall have low and constant contact resistance, generally tens of meters ω To several hundred meters ω。

3. Environmental performance.

Temperature resistance, moisture resistance, salt spray resistance, vibration and impact resistance are the main environmental properties of the connector. Select according to the specific application environment. If the application environment is humid, the requirements for moisture resistance and salt spray resistance of the connector are very high to avoid rust of the metal contact of the connector. In the field of industrial control, the requirements for the anti vibration and impact of the connector are very high, so as to avoid the connector falling off in the process of vibration.

4. Mechanical properties.

The mechanical properties of the connector include pulling and inserting force, mechanical anti stupidity, etc. Mechanical anti stupidity is very important for the connector. Once inserted reversely, it is very likely to cause irreversible damage to the circuit!

The insertion force is divided into insertion force and separation force. Relevant standards specify the maximum insertion force and minimum separation force. From the perspective of use, the insertion force is small and the separation force is large. Too little separation force will reduce the reliability of contact. However, for connectors that often need to be plugged in and out, too much separation force will increase the difficulty of plugging in and out and reduce the mechanical life.

Shenglan Technology Co., Ltd_ It focuses on the production of electronic connectors and research and development of precision components. Its products are widely used in consumer electronics, new energy vehicles, USB, 5g and other fields. Its industrial lines cover the Pearl River Delta, Southeast Asia and other regions. It has established long-term strategic cooperation relations with well-known enterprises such as Foxconn, Lixun precision, Huawei, Xiaomi, TCL, Hitachi Group, BYD and Great Wall Motors, with IATF 16949, ISO9001 ISO14001, QC080000 and other system certification and product safety certification, and provide professional connection and manufacturing solutions for the industry http://jctc.com.cn/