Test of connector solutions in driverless and new energy electric vehicle applications

People describe cars as "computers on wheels" because they are combined with electrical, electronic, software and mechanical components.

The emergence of driverless and new energy electric vehicles is gradually replaced by the E / E (electronic / Electrical) architecture of vehicles.

1. Driverless

In the embedded operating system, the computer capacity is gradually limited by the technology of a single controller. The bandwidth of intra domain and cross domain communication is likely to be unable to meet the future data information transmission. Although the floating board to board connector plays an important role in the field of unmanned applications, this technology is challenging.

2. New energy electric vehicle

The design of new energy electric vehicles involves vehicle control unit (VCU), motor control unit (MCU), on-board charger (OBC), power distribution unit (PDU) and DC conversion (DC-DC), and the power module and control board of the charging station.

As the demand of Shiyang for driving mileage is gradually increasing, the main development trend of nev is the transition of Shiyang from plug-in hybrid and hybrid new energy electric vehicles. It is expected to transition from new energy electric vehicles to fuel cell vehicles in the future.Moreover, the transition from standard Huai VDA battery module to a large module with a higher proportion of battery pack (CTP) can improve space utilization, increase energy density, and reduce the total weight of the battery pack by reducing the total amount of spare parts.

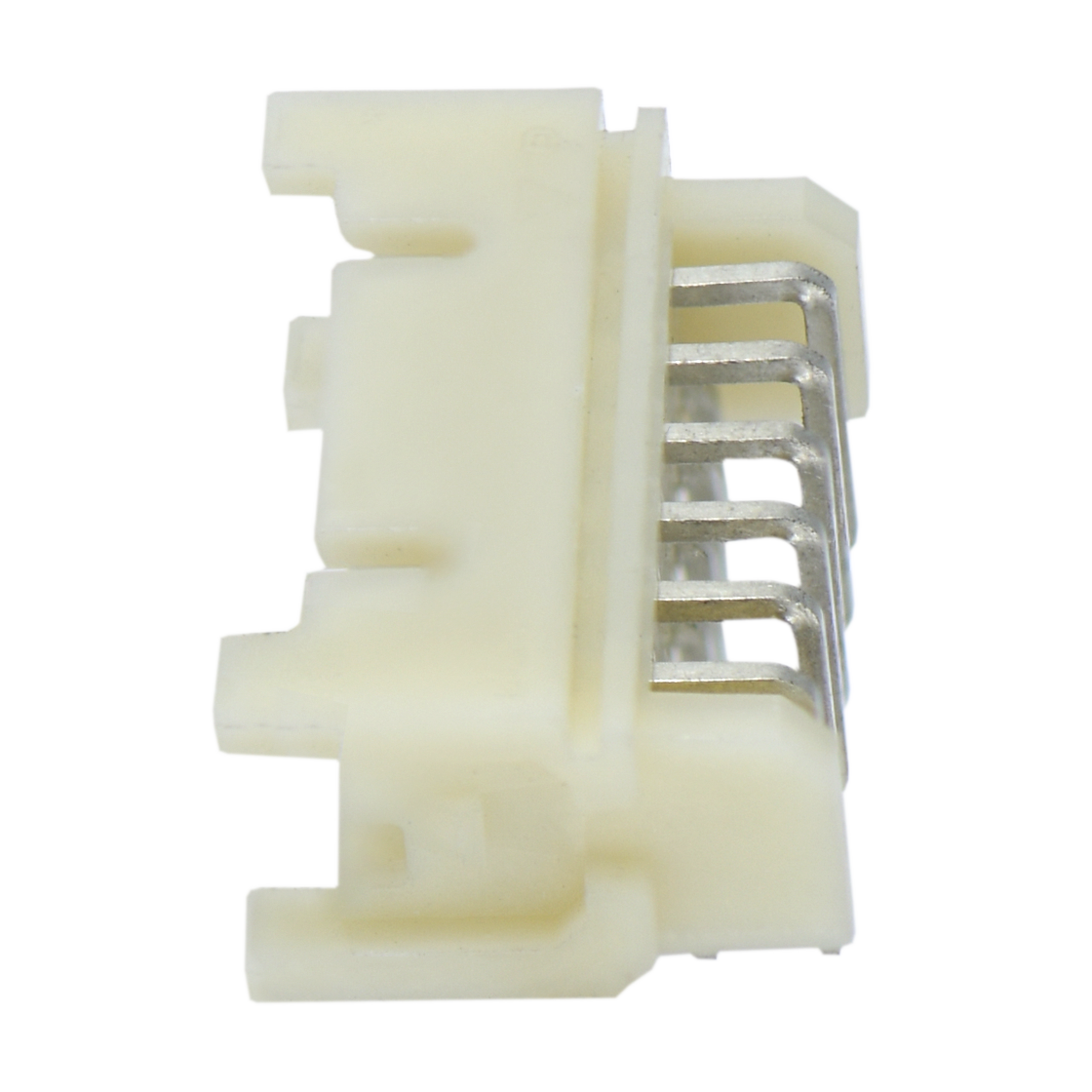

At this stage, the connector solution is facing many tests in NVE, that is, reducing the dead weight of the vehicle. The EV battery pack occupies a large part of the total weight of the whole vehicle and also occupies a large amount of space. Compared with the traditional harness, these elements require smaller and lighter connectors.

Flexible printed circuit board (FPC) can also be used as a substitute for traditional line to board connectors to provide lighter products. At the same time, the flexibility of the product allows it to be used in a compact space, which is also required by the high-density multi battery structure inside the current top battery pack. Therefore, it can solve the problem of space limitation faced by automotive electronics.

The FFC / FPC connectors produced by Shenglan Technology Co., Ltd. are used in various fields such as electronic instruments, such as computer peripherals, measuring instruments and equipment, and also produce more than 500000 high-quality connector products such as new energy electric vehicle charging connectors and power connectors.