How can enterprises reduce the risk of interruption in the supply chain of electronic components?

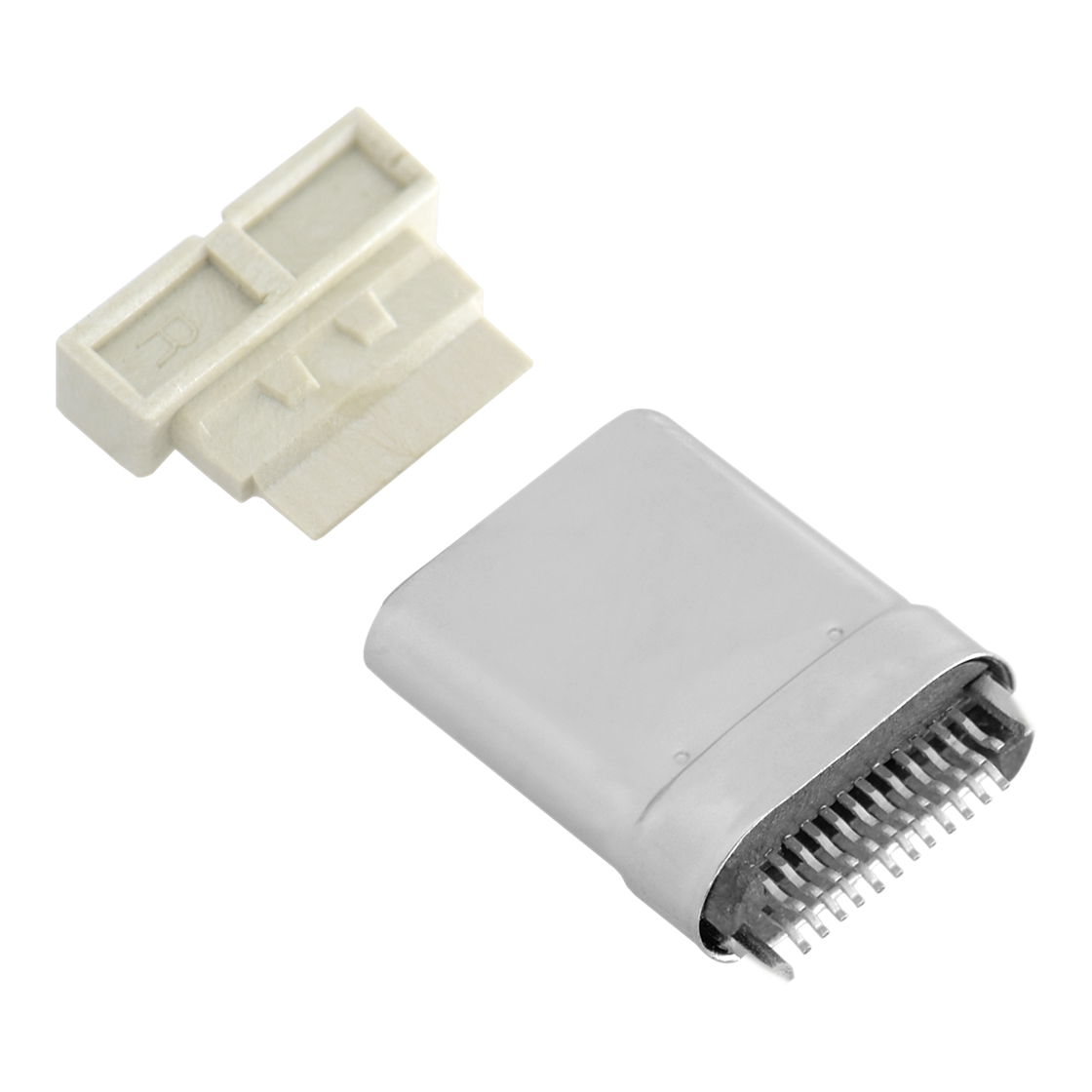

How to optimize the supply chain?It usually requires the purchase manager, supply management, material manager and supervisor, and purchase engineer to discuss the supply chain management course together 。as if What are you in the enterprise The above roles will be Participate in how to reduce Discussion on the risk of supply chain interruption. For Electronics Components (connectors)As far as the industry is concerned, this topic has a richer and deeper discussion. Given the dynamics of today's market, buyers must have a reliable source of alternative electronic components to mitigate risks and avoid interruptions.

existing Many people rely on Wanlian mall as their preferred resource for electronic parts in a stable supply chain environment and inevitable interruption. Wanlian mall has more than one million parts available in the electronic component Market - all parts are guaranteed, traceable and 100% guaranteed. With the competitive price structure of Wanlian mall, buyers can find and buy electronic components that are difficult to find for a long time while managing budget constraints.

These characteristics are very important for the search for alternative electrons Components (connectors)It's priceless for buyers. Moreover, it seems that the need for alternative part strategies is more important than ever. Let's take a look at the three realities that challenge today's supply chain and what help Wanlian mall can provide.

Three factors challenging buyers of electronic components.

1. Shortening the service life of electronic products.

The rapid pace of technological development has shortened the shelf life of electronic products. The service life of these products (usually their electronic components) was previously in years and now in months. This will make buyers scramble to find tail Or electronic parts that are no longer manufactured.

2. Global turmoil

The global supply chain has suffered numerous natural disasters and man-made destruction. Most enterprises have some kind of strategic plan to deal with all uncertainties. However, these plans often fail to stop the interruption of the supply chain. After the devastating earthquake and tsunami in Japan in 2011, Mitsubishi electromechanical company found that more than 200 suppliers were located in the affected areas. Although they have previously identified alternative electronic component suppliers, it takes three months to test these suppliers. Despite planned efforts, Mitsubishi still has no electronic parts.

3. Acquisition and merger of electronic components industry

Last year, M & A activity in the electronic components industry reached the highest level in 12 years. The stable performance in recent years is that many companies have a lot of funds, which increases the opportunities for M & a growth. In order to improve profit margins, the company has acquired competitors or sold underperforming product lines. With the increasing demand for integrated system products, some companies are jointly providing more interconnected solutions. However, sometimes M & A activities can catalyze the reduction of parts types, so that some supply chains do not have the parts supply they once relied on.

As the supply chain becomes more and more complex, the supply chain risk management strategy will continue to cause discussion. The demand for reliable alternative parts suppliers will become the core part of these dialogues.

The proposed alternative parts function makes Wanlian mall's online parts market the preferred resource for alternative parts buyers, and its transparent pricing structure makes Wanlian mall a trusted daily operation partner. Wanlian connects sellers with more than 750 electronic parts manufacturers through a searchable inventory of available parts valued at more than $10 billion. Let higher quality connections create a steady stream of value!