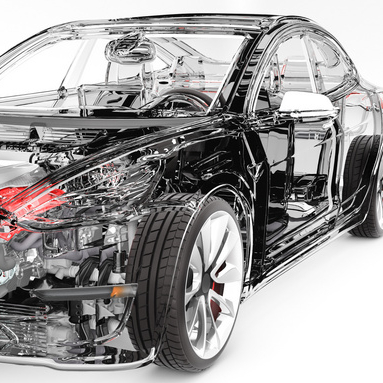

Production process of automobile wire harness

The low-voltage power control harness assembly of the new electric vehicle changes the direction of the harness, with beautiful appearance, easy identification, and maintenance. The harness fixing tab is added to solve the vibration and wear problems of the vehicle in driving. The waterproof fixing rubber is added to prevent the harness from oxidation or dysfunction. The harness has good safety and stability. The assembly technology scheme has humanized design and powerful functions compared with the traditional truck door harness, which greatly improves the safety and durability of vehicle operation.

The tail sleeve of the elastic clip fixed by the harness is provided with a gear. The automobile harness manufacturer shall set a spring between the bottom of the slot where the gear and harness are fixed and captured, and the spring collision block can contact the tail elasticity of the elastic clamp head.

After the elastic clip is inserted into the clip hole, the elasticity of the spring can not only improve the vibration cushioning performance, but also ensure the stability of the elastic clip connection. Since the inside of the buckle and the bottom of the slot of the harness fixing clip are fixed with sponge pads, if they are buckled, the harness will be closed in the slot and installed reliably under the action of the sponge pads.

The connector is moved to the engine compartment for easy search and maintenance. Use a variety of waterproof connectors to prevent connector inflow, inflow oxidation or functional failure problems. Change the direction of the harness to make the entire harness assembly easier to view, identify, and repair. T-shaped sleeve is added to solve the problem of vibration and wear of harness during driving.

The new engine harness assembly has a beautiful appearance and is easy to repair compared with the traditional engine harness assembly. The safety, water resistance and durability of vehicle operation have been greatly improved.

To sum up, the assembly process and production process inspection technology of automobile wire harness can use new automobile wire harness optimization control. The introduction of these devices not only improves the efficiency of maintenance and inspection, but also prevents each connector from occurring due to water oxidation or functional failure. To this end, researchers must put its role through practice to improve the overall effectiveness of automobile wire harness assembly production.