Six obstacles in high voltage connector design

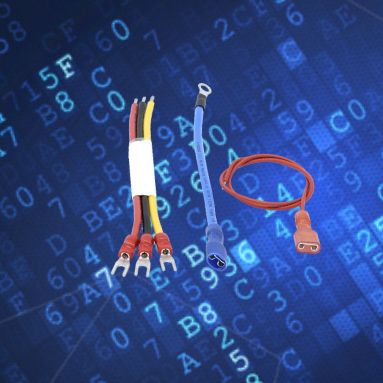

The design of high voltage cable assemblies and connectors is very challenging, and many aspects of cable assemblies must be considered.

1. Size limits.

Size constraints often make the design of high voltage connectors and cable assemblies particularly difficult. Generally speaking, the high-voltage cable assembly is the last problem that customers need to consider when designing equipment.

In order to meet the working requirements, the space required for high-voltage connection is required. The industry is moving towards smaller and lighter components with higher working thresholds. Using space to counteract high pressure has become a thing of the past.

Many companies now hope that the design team can propose effective solutions to solve these problems and reduce the cost of cable components. The custom connector design in electronic Valley mall can meet this goal.

2. Design around existing connectors.

It is very difficult to prove the design around the existing connector. Users often recommend using existing connectors that they cannot discard. Generally speaking, the performance of these connectors does not meet their requirements, or they are matched with other components of veteran equipment in their design.

Another reason is that the connector needs to work at higher performance thresholds that the current configuration cannot meet. In any case, it is necessary to deeply analyze the internal working principle of the connector assembly. For example, through close cooperation with users, Shenglan technology engineering team needs to analyze all aspects of design: what materials are used? What are the mechanical and electrical properties of these materials? What aspects of the design can be modified to meet the required specifications without affecting the design, installation, form and function?

3. Cost.

Under the current economic situation, one of the main obstacles in the design of high-voltage meter is to reduce the cost. It is difficult to prove that designing a reliable, efficient and robust connector even exceeds the requirements of users. In many cases, performance eventually has to reduce costs.

Some techniques can be used to minimize costs without affecting performance. For example, use inventory and available existing materials, use hardware in existing design, integrate it into new design, use existing tools, molds and fixtures, and use cost-effective materials that do not affect performance to design new components.

4. Manufacturability.

Manufacturability is an important part of design. The design on paper may be beautiful, but is it easy to make? Design difficulty affects the direct labor time required to build cable components, which in turn affects the cost.

Design difficulty also affects the ability to maintain repeatable and reliable technology. If the technology cannot be repeated, an internal cable failure may be encountered. These potential technical problems shall be found and solved during the design review.

5. Materials.

It is very important to select the correct materials that meet the required performance characteristics and maintain the design efficiency. High voltage cable assemblies and connectors require materials with good electrical and mechanical properties.

Careful analysis of the working environment and its impact on materials is the key. It is easy to go wrong with different materials. Good adhesion between materials is particularly important when trying to counteract high pressure. If there is no good adhesion between materials, the voltage can not be offset to receive air, which requires a greater distance between the high voltage and the ground when designing components.

Use the same material to support the bonding and binding between materials, so as to effectively offset the high voltage and allow smaller connectors. If different materials are used in the design, it is very useful to use paint and adhesion promoter, depending on the material you want to bind.

6. Coronal protrusion.

Crown less design is sometimes really difficult. The designed crownless cable assembly can ensure reliability and elasticity and stand the long-term test.

There are many factors that must be considered when designing the headless cable assembly. First, select the correct cable. Most designs use triple extruded cables. This ensures the smoothness and uniformity of the conductor and the ground. The second is the connector interface. The interface shall have sufficient distance to counteract the applied voltage and air.

Tips for avoiding design obstacles:

(1) Size: consider the cable assembly or connector structure as soon as possible. High pressure may require more space than you think.

(2) Use an existing design: if you need to modify an existing design, it is best to consult a custom designer to ensure that they can meet your new requirements.

(3) Cost: don't be too attached to cost. Reliable, durable and safe design is cheaper in the long run.

(4) Manufacturability: don't over design. Your expectations are more realistic. Sometimes the simpler the better.

(5) Materials: in order to ensure the best and most reliable binding between dielectrics, the same materials shall be used.

(6) Coronal / partial discharge: the geometry of the connector is very important. The sharp angle is like a coronal antenna. All sharp edges shall be as round as possible.