Several common forms of terminal failure

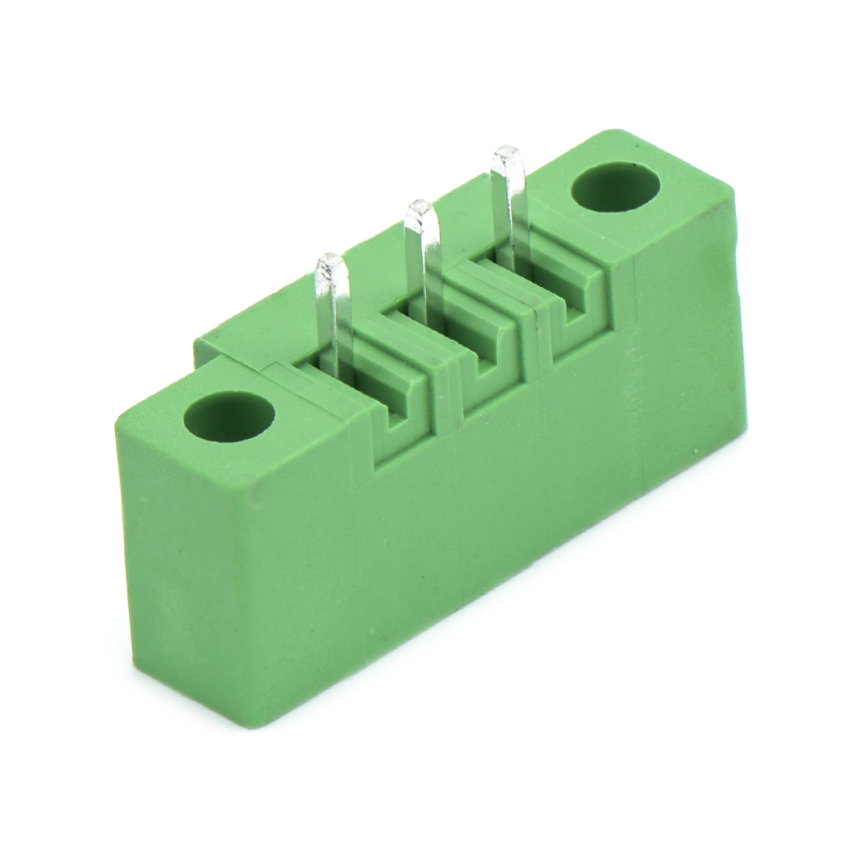

Terminal block The plastic insulating material and conductive parts are directly related to the quality of the terminal and determine the insulation and conductivity of the terminal. whatever Terminal block All faults will lead to the failure of the whole system engineering.

Prevention is the purpose and analysis is the basis. In a sense, failure prevention is more important than failure analysis. It has more practical significance to ensure the quality and reliability of terminals.

From a usage perspective,Terminal block It shall have the following functions: the contact part must be conductive and reliable. The place where the insulation part should not be connected must be insulated reliably. Terminal blocks have three common forms of fatal faults:

1. Poor contact.

The metal conductor inside the terminal is the core component of the terminal, which transmits the voltage, current or signal of the external wire or cable to the contact component corresponding to its matching connector. Therefore, the contact must have good structure, stable and reliable contact maintenance and good conductivity. Due to unreasonable contact structure design, wrong material selection, unstable mold, poor processing size, rough surface, unreasonable surface treatment processes such as heat treatment and electroplating, improper assembly, poor storage and use environment, improper operation and use, the contact parts and mating parts of the contact will cause poor contact.

2. Poor insulation.

The function of the insulator is to keep the contact arranged in the correct position, so as to insulate the contact from the contact and the contact from the shell. Therefore, insulating parts must have excellent electrical properties, mechanical properties and process molding properties. Especially with the wide use of high-density and small wiring terminals, the effective wall thickness of insulators is getting thinner and thinner. This puts forward stricter requirements for insulating materials, injection mold accuracy and molding process. Damp due to excessive metal on the surface or inside of the insulator, surface dust, flux and other pollution., The organic sediment and harmful gas adsorption film are fused with the surface water film to form ion conductive channels, moisture absorption, mildew, aging of insulating materials, etc. It will cause short circuit, leakage, breakdown, low insulation resistance and poor insulation.

3. Poor fixation.

The insulator not only performs the function of insulation, but also usually provides accurate neutralization protection for the protruding contacts. At the same time, it also has the functions of installation, positioning, locking and fixing on the equipment. Poor fixation, light impact, reliable contact, resulting in instantaneous power failure, and serious product disassembly. Disassembly refers to the serious consequences of unreliable structure of the wiring terminal in the inserted state due to materials, design, process and other reasons, resulting in abnormal separation of plug and socket, pin and Jack, and interruption of power transmission and signal control of the control system. Due to unreliable design, wrong material selection, improper selection of forming process, poor process quality of heat treatment, mold, assembly and welding, improper assembly, etc.

In addition, poor appearance caused by coating peeling, corrosion, bruise, plastic shell flash, fracture, rough processing and deformation of contact parts, poor exchange caused by out of tolerance of positioning and locking fit size, poor consistency of processing quality, excessive total separation force and other reasons are also common and frequently occurring diseases. These faults can usually be found and eliminated in time during inspection and use.

Reliability screening inspection to prevent failure.

In order to ensure the quality and reliability of the terminal and prevent the occurrence of the above fatal faults, it is recommended to study and formulate corresponding screening technical requirements according to the technical conditions of the product, and carry out the following targeted reliability inspection to prevent the occurrence of faults.

1. Prevent poor contact.

1) Continuity detection.

At present, the product acceptance test of general wiring terminal manufacturers does not have this item, and the user generally needs to conduct continuity test after installation. Therefore, it is suggested that manufacturers should increase 100% point by point conduction detection for some key models of products.

2) Instant detection.

Some terminals are used in dynamic vibration environments. Experiments show that only checking whether the static contact resistance is qualified can not ensure the reliability of contact in dynamic environment. Because the connectors with qualified contact resistance still have instantaneous power failure during vibration, impact and other simulated environmental tests, it is best to conduct 100% dynamic vibration test on some wiring terminals with high reliability requirements to evaluate their contact reliability.

3) Test the separation force of single hole.

Single hole separation force refers to the separation force of the contactor in the inserted state from stationary to moving, which is used to represent the contact between the pin and the jack. The experimental results show that the single hole separation force is too small, which may lead to instantaneous signal fracture under vibration and impact load. It is more effective to check the contact reliability by measuring the single hole separation force than to measure the contact resistance. It is found that the contact resistance of the jack with out of tolerance single hole separation force is often qualified. Therefore, in addition to developing a new generation of flexible plug-in contacts with stable and reliable contact, the manufacturer should not use the automatic plug-in tester to conduct multi-point measurement on key models, but should conduct 100% point by point single hole separation force inspection on the finished products, so as to prevent instant signal fracture caused by individual Jack loosening.

2. Prevent poor insulation.

1) Check insulation.

The quality of raw materials has a great influence on the insulation performance of insulators. Therefore, the choice of raw material manufacturers is particularly important. We can not blindly reduce costs and lose material quality. We should choose large-scale materials with good reputation. And carefully check the batch number, material certificate and other important information of each batch of materials. Do a good job in the traceability data of material use.

2) Insulation resistance inspection of insulator.

Now, the process of some manufacturers stipulates to test the electrical performance after assembling the finished products. As a result, the insulation resistance of the insulator itself is unqualified, so the whole batch of finished products can only be scrapped. Reasonable process shall be 100% screened under the condition of insulating parts to ensure qualified electrical performance.

3. Prevent poor fixation.

1) Interchange check.

Exchange check is a dynamic check. It requires that the same series of matched plugs and sockets can be inserted and connected with each other to find out whether they cannot be inserted, positioned and locked due to out of tolerance of insulator, contact and other parts, missing parts or inadequate assembly, or even disassembled under the action of rotating force. Another function of exchange inspection is to timely find out whether there are metal residues affecting insulation performance through plug-in connection such as threads and bayonets. Therefore, terminals for some important purposes should be 100% inspected to avoid such major fatal failures.

2) Torque resistance inspection.

Torque resistance inspection is an effective method to evaluate the reliability of terminal structure. For example, the U.S. military standard mil-l-39012. According to the standard, each batch shall be sampled to check the endurance moment and find problems in time.

3) Through test of crimping wire.

It is often found that individual core voltage wiring cannot be sent in place during electrical installation, or cannot be locked after being sent to the position, and the contact is unreliable. The reason is that there are burrs or dirt stuck on the screw teeth of individual mounting holes. In particular, the user has been electrically installed into the last few mounting holes of a plug base. After finding this defect, he has to remove other installed hole pressure wiring one by one and replace the plug base again. In addition, due to the improper selection of wire diameter and crimping aperture, or due to the wrong operation of crimping process, the crimping end will also be unstable. Therefore, the manufacturer shall conduct a general test on all mounting holes of the delivered plug (seat) sample before the finished product leaves the factory, that is, touch the wire with pin or socket in place with a loading and unloading tool to check whether it can be locked. Check the pull-out force of each crimping wire according to the technical conditions of the product.

Shenglan Technology Co., Ltd_ It focuses on the production of electronic connectors and research and development of precision components. Its products are widely used in consumer electronics, new energy vehicles, USB, 5g and other fields. Its industrial lines cover the Pearl River Delta, Southeast Asia and other regions. It has established long-term strategic cooperation relations with well-known enterprises such as Foxconn, Lixun precision, Huawei, Xiaomi, TCL, Hitachi Group, BYD and Great Wall Motors, with IATF 16949, ISO9001 ISO14001, QC080000 and other system certification and product safety certification, and provide professional connection and manufacturing solutions for the industry http://jctc.com.cn/