Common terminal types

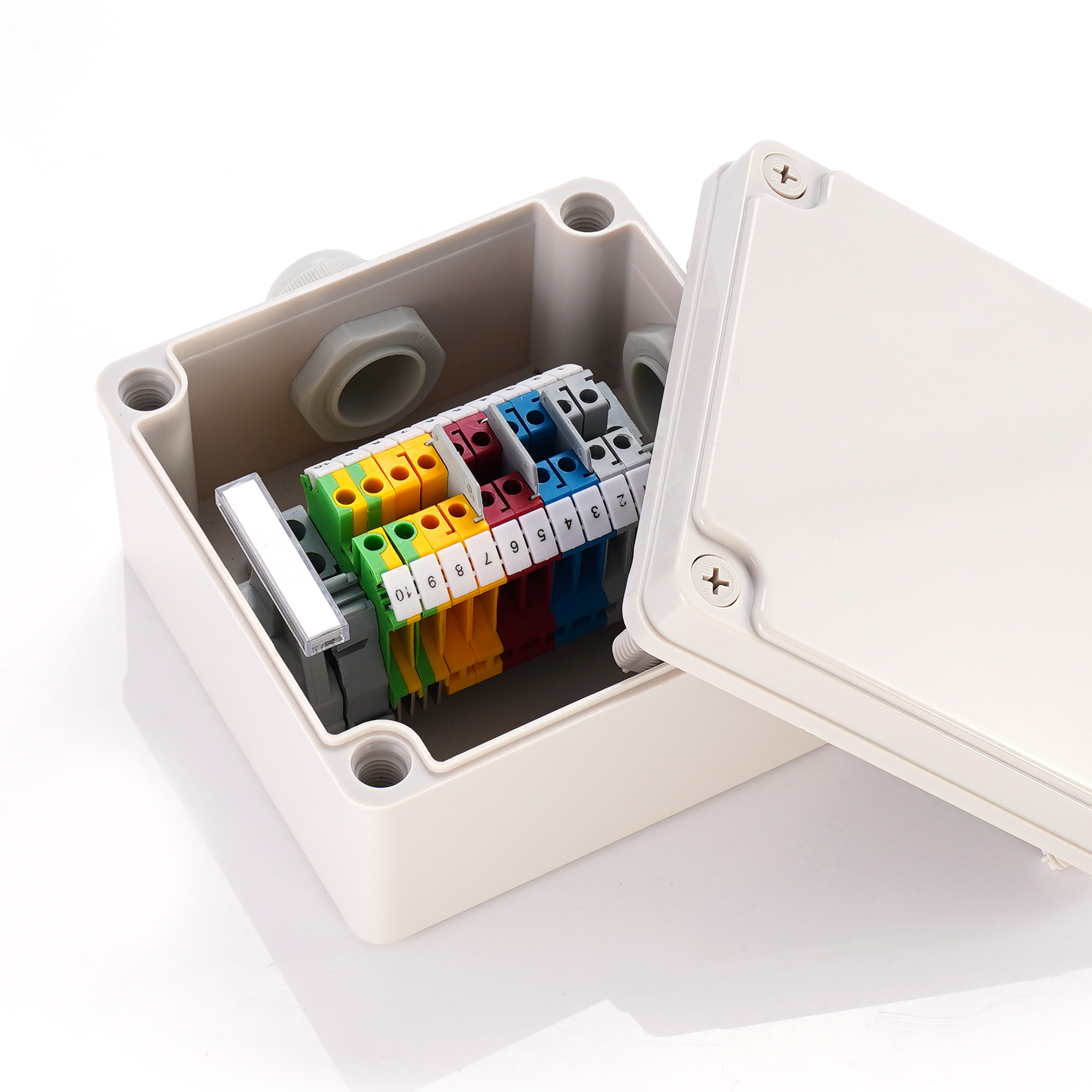

Terminal block The design is simple, but choosing the right terminal block for your application may be complex. Terminal block, also known as screw terminal, terminal connector or connecting terminal, is used to connect multiple lines safely and reliably. They provide engineers with semi permanent connections in a variety of applications.

PCB installation, isolation band and feedthrough are the three most common types of terminal blocks.

Printed circuit board (PCB) mounting terminal block:

1. Or: wire pair board Terminal block Or European style Terminal block 。

2. Installation method: directly welded to the printed circuit board.

3. Configuration: single line, double line, multi line.

4. Usage: insert the bare wire into the module, and then firmly fix the clip in the housing.

Isolation belt:

1. Used when vibration is required.

2. Installation method: tighten the terminal to accommodate bare wire or end wire.

3. Configuration: single line, double line, multi line.

4. Usage: insert the cable and tighten the screw.

Straight through Terminal block :

1. Used to establish a line to line connection.

2. Configuration: single line, double line, multi line.

3. Usage: insert two separate wires into the opposite sides of the shell and connect them together.

Electrical specifications.

Select terminal The most important specification that should be considered when designing a block is its current rating. The three specific areas that should be considered are the conductivity, cross-sectional area and corresponding temperature rise of the terminal. If the terminal operates at high current, it may overheat and damage the connection - causing serious safety hazards. It is a good rule of thumb to select terminals with a rated current of at least 150% of the maximum current expected by the system.

The rated voltage shall also be greater than the maximum system voltage. With this in mind, surge must be considered to prevent connection damage. The rated voltage is a function of the insulation strength and spacing of the junction box housing.

The number of poles is the next issue to consider. Consider how many independent circuits the terminal strip will accommodate. In general, the range can range from unipolar to 24 poles in the block.

Spacing is the center distance between adjacent poles. These usually occur at various distances between 2.54 mm and 10 mm. The spacing is determined by the overall rating of the junction box, taking into account factors such as power creep, voltage / current and clearance.

Terminals usually receive wires of various sizes. These are specified by the wire rules (AWG) of North America. However, in Europe, the wire size represents the cross-sectional area in square millimeters, so it is very important to ensure correct conversion. The smaller the gauge unit, the larger the wire diameter. Engineers should also consider the type of wire. The push end is usually used for single core wires, while the screw end is more suitable for multi-core or multi-core wires.

Although the design of the junction box is relatively simple, it has a variety of shapes and sizes. By understanding the precautions listed in this article and the advantages and disadvantages of different types of terminal blocks, engineers can ensure that they choose the correct solution for this work. The user interface device provides terminal blocks with multiple color choices, as well as various electrical and mechanical specifications to help simplify the selection process.

Shenglan Technology Co., Ltd_ It focuses on the production of electronic connectors and research and development of precision components. Its products are widely used in consumer electronics, new energy vehicles, USB, 5g and other fields. Its industrial lines cover the Pearl River Delta, Southeast Asia and other regions. It has established long-term strategic cooperation relations with well-known enterprises such as Foxconn, Lixun precision, Huawei, Xiaomi, TCL, Hitachi Group, BYD and Great Wall Motors, with IATF 16949, ISO9001 ISO14001, QC080000 and other system certification and product safety certification, and provide professional connection and manufacturing solutions for the industry http://jctc.com.cn/