Analyze the usage and function of terminal block

I Terminal block Row usage

1. Screw connection.

Screw connection adopts the connection mode of screw terminal block. The key is to allow the maximum and minimum sections of connecting wires and the maximum tightening torque of threads of different specifications.

2. Welding.

Welding is the most common way. The most important thing of welded connection is the continuity of metal formed between the welding material and the welded surface. Therefore, solderability is very important for cold pressed terminals. The most common coatings on the welding end of the terminal ring are tin alloy, silver and gold. Common welding ends of reed contact include welding plate, punching welding plate and notch welding plate (common welding ends of pinhole contact include drilling arc notch type).

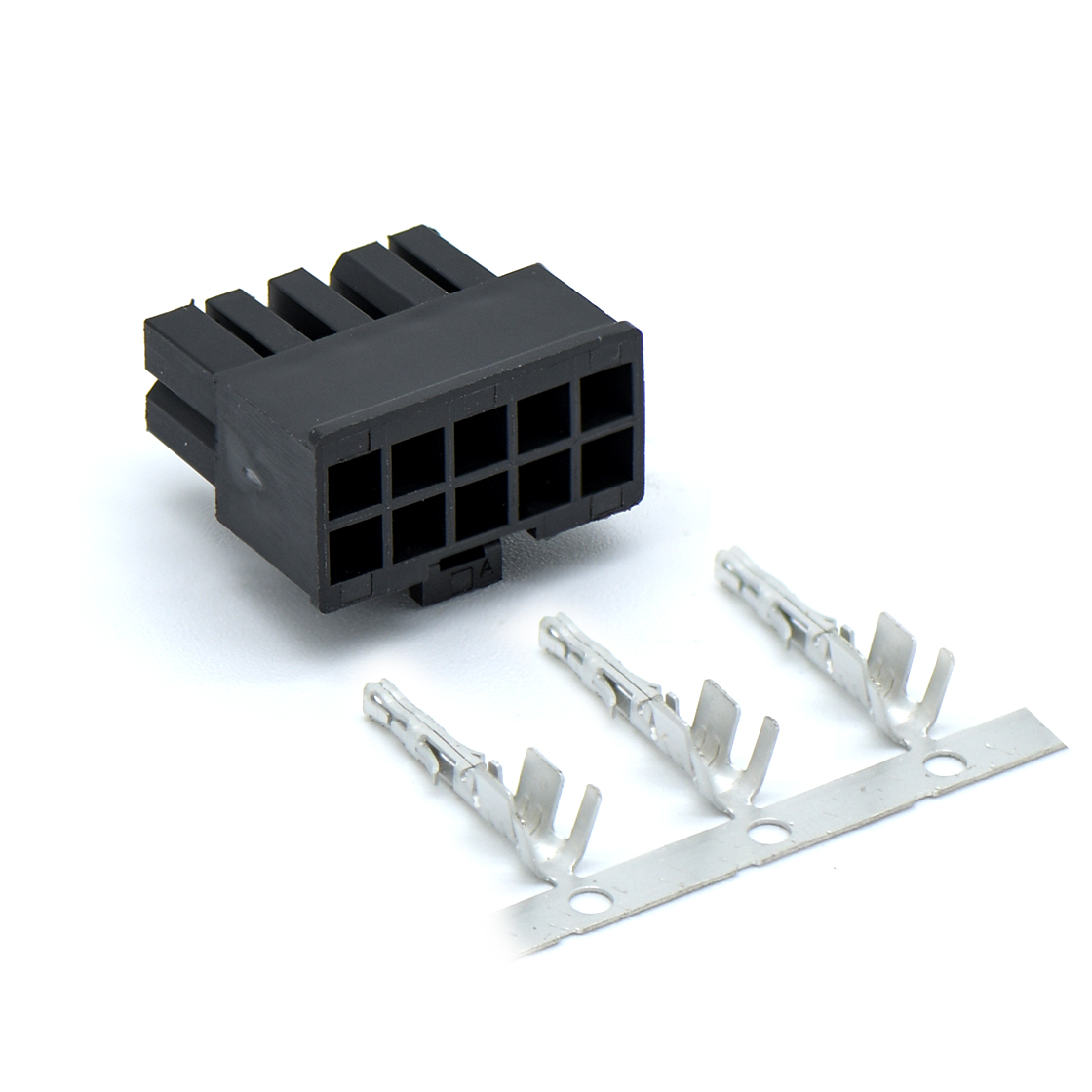

3. Crimp.

Crimping is a technique for connecting wires to contact pairs so that metals can compress and displace within specified limits. Good crimping connection can produce the flow of mutual melting of metals, making the conductor and contact symmetrically deform the material. The connection is similar to cold welding connection, which can obtain good mechanical strength and electrical continuity, and can withstand worse environmental conditions. At present, it is generally believed that correct crimping connection is better than tin welding, especially in high current occasions. Professional crimping pliers or automatic and semi-automatic crimping machine must be used for crimping. Correctly select the conductor barrel of the contact pair according to the conductor section of the cold crimping end. It should be noted that the crimp connection is a permanent connection and can only be used once.

4. Winding.

Winding is to wind the conductor directly on the winding column of the angular contact. When the wire is wound under tension control, it is pressed in and fixed at the edges and corners of the contact winding column to form an air tight contact. There are several requirements for wound conductors: the nominal value of conductor diameter shall be in the range of 0.25mm to 1.0mm; When the diameter of the conductor is not more than 0.5mm, the copyright ownership of the engineering network shall be controlled, and the elongation of the conductor material shall not be less than 15%; When the diameter of the conductor is greater than 0.5mm, the copyright ownership of the engineering network shall be controlled, and the elongation of the conductor material shall not be less than 20%. The winding tools include winding gun and fixed winding machine.

5. Pierce one after another.

Also known as insulation displacement connection, it is a new end technology invented by the United States in the 1960s. It has the characteristics of high reliability, low cost and convenient use. Now it has been widely used in various printed board wiring terminals, cold pressing terminals and ring terminals. It is applicable to the connection of ribbon cable. During connection, it is not necessary to peel off the insulating layer of the cable, but the tip of the U-shaped contact spring of the terminal shall be used to pierce the insulating layer, so that the conductor of the cable can slide into the groove of the contact spring, clamp the ownership of the copyright of the control engineering network, and form a tight electrical connection between the cable conductor and the spring of the terminal. It only needs simple tools, but the specified cable must be selected.

II Terminal block The role of drainage.

Terminal block is an accessory widely used in electrical engineering and plays a main role of fixing device in series combination. The number of terminals in each row is different, which should be selected according to their own needs, which is related to the parameters of each product.

The application of terminal block is reflected in many aspects, which is used for power electronic wiring. In addition, when the screen device is connected to internal devices and external devices, such a device is required to transmit signals.

With this equipment, the line becomes more regular, not only very beautiful, but also easy to check problems in the future. It plays a very important role and is widely used. On this equipment, English letters or Pinyin and numbers are usually used to display the maximum contact current, which is a standard that must be paid attention to in use.

The raw materials of the terminal block are very important. Good quality can ensure that there will be no leakage in use, bring everyone a safe environment during work, and prolong the service time of the goods. Good product corrosion resistance is also important. Sometimes it is inevitable to encounter some acid and alkali substances, and short-term touch will not cause damage to the accessories themselves. At the same time of external insulation, it is also necessary to ensure the outstanding performance of internal conductivity to ensure normal use.

Shenglan Technology Co., Ltd_ It focuses on the production of electronic connectors and research and development of precision components. Its products are widely used in consumer electronics, new energy vehicles, USB, 5g and other fields. Its industrial lines cover the Pearl River Delta, Southeast Asia and other regions. It has established long-term strategic cooperation relations with well-known enterprises such as Foxconn, Lixun precision, Huawei, Xiaomi, TCL, Hitachi Group, BYD and Great Wall Motors, with IATF 16949, ISO9001 ISO14001, QC080000 and other system certification and product safety certification, and provide professional connection and manufacturing solutions for the industry http://jctc.com.cn/