Difference between coaxial line and coaxial output connector

Coaxial output components have been widely used in frequency radiation application or microwave heating application, but some RF signals must be imported by light wave or plan coaxial cable to carry out reasonable transmission. Therefore, the application examples of coaxial output components in various places can be found, including components, desktop all-in-one computer instruments and equipment or mechanical equipment, indoor, outdoor, airport, land vehicle, mechanical equipment, intelligent robot, space shuttle, communication satellite, etc. Because its application scope is very common, there are all kinds of coaxial lines and connectors with technical characteristics. The technical assembly of this kind of coaxial output is as complicated as before, so it must rely on special tools of technical specialty.

However, some common coaxial lines and connectors are assembled by using special tools and methods of standard series products. The standardized coaxial line was first used in the national defense industry. "Wireless communication manual" or RG coaxial line originated from the Second World War and was incorporated into British mil-hdbk-216 (British military industry guide-216) in 1962. Since then, RG coaxial line has gradually become more and more widely. This leads to the universal special tools and practical activities of RG coaxial line components, including manual tools and practical activities in machinery and equipment, or during installation or maintenance. Although many coaxial lines contain additional layers, a typical RG type coaxial line consists of four layers. The four basic layers of the coaxial line are: surface protective shell (conductor and insulator), metal material shielding layer, electric polarization conductor and insulator and electric conductor of the management center. Except that the surface protective shell is different, the design scheme of coaxial output connector is basically the same. In essence, the metal material shielding layer or external conductor of the coaxial line must be uniformly connected with the surface shielding layer of the coaxial output connector as far as possible, and the electrically polarized conductor and insulator must be connected with the coaxial output connector in the same way, so as to greatly reduce the characteristic impedance transformation, In addition, the electrical conductor of the management center must be uniformly connected with the coaxial output connector as far as possible.

Operation steps:

To connect this connector, first of all, the surface protective shell of the coaxial line must be removed. The total number is generally referred to the total number of tail ends of the coaxial line cut by fine laser.

In addition, the parallelism of the cable can not be reduced, and there are no residual metal material fragments in the conductor and insulator. Generally, special tools with accurate design scheme shall be prepared in advance to remove the surface protective shell. It is committed to the actual operation of removing the surface protective shell without damaging the surface shielding layer. After disassembly, the shielding layer of foil, wavy or stranded electrical conductor shall be mechanically and automatically solved to make it consistent with the external electrical conductor fixing card of coaxial output connector. After the whole process, the polarization conductor and insulator on the electrical conductor of the management center can be separated, so that the electrical conductor of the management center can be welded, riveted or riveted to the pin fixture of the coaxial output connector management center.

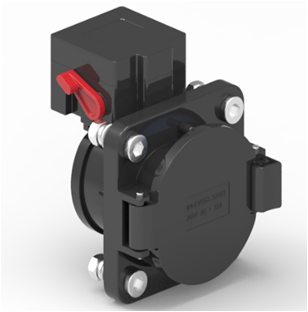

A metal ring is usually attached to the coaxial output connector, which is used to lift the mechanical equipment connector of the external electrical conductor of the cable and ensure excellent frequency emission shielding. Once the coaxial line and coaxial output connector are combined by riveting, electric welding or other methods, heat shrinkable sleeve or adhesive tape will generally be added to ensure that the surface protective shell of the coaxial line and the sleeve in the middle of the coaxial output connector are more firmly connected. Heat the shrink sleeve or adhesive tape at the connection between the cable and the connector, which can reduce the strain force at the connection between the electrical conductor and the electrolytic medium, and ensure that the coaxial output parts can still operate again as expected under some strain force, load or bending conditions.